Optical coating refers to the process of plating a layer (or multilayer) of metal (or medium) film on the surface of optical parts. The purpose of coating the surface of optical parts is to reduce or increase the reflection, beam separation, color separation, light filtering, polarization and other requirements,Commonly used coating method has vacuum coating (a physical coating) and chemical coating. What are the typical thin-film system designs for optical coating? Today we will look specifically at the typical membrane system in optical thin film system design.

Film design in optical coating system with antireflection film, reflection film, band pass filter, cut-off filter, polarization film and depolarization film and other optical films, today we will specifically look at the detailed characteristics of these films and the usage?

Antireflection film, antireflection film has very low residual reflection in narrow band and wide band range, for example, residual reflection on narrow band <0.1%, the average residual reflection on wide band <0.3% and so on. It is used to reduce the reflectivity of various refractive index optical surfaces to be used in various optical systems with monochromatic light source or white light source such as laser wavelength. The commonly used 3 or 4 layers of film can cover the visible region, but the design and preparation of antireflection of wider band are more difficult.

Reflection film, reflection film metal reflection film, metal dielectric reflection film and all dielectric reflection film. Although metal reflection film has broadband reflection characteristics, but because of low absorption reflectivity, the reflectivity of common metal mirror is about 90%, and the reflectivity of dielectric reflection film can reach about 99.8%,Optical reflection bandwidth, reflectance, firmness and cost, choose different reflectance film to improve the reflectance of optical devices, metal reflector is often used for broadband reflection but reflectance requirements are not high occasions, all medium reflector is often used for laser technology is very high reflection occasions.

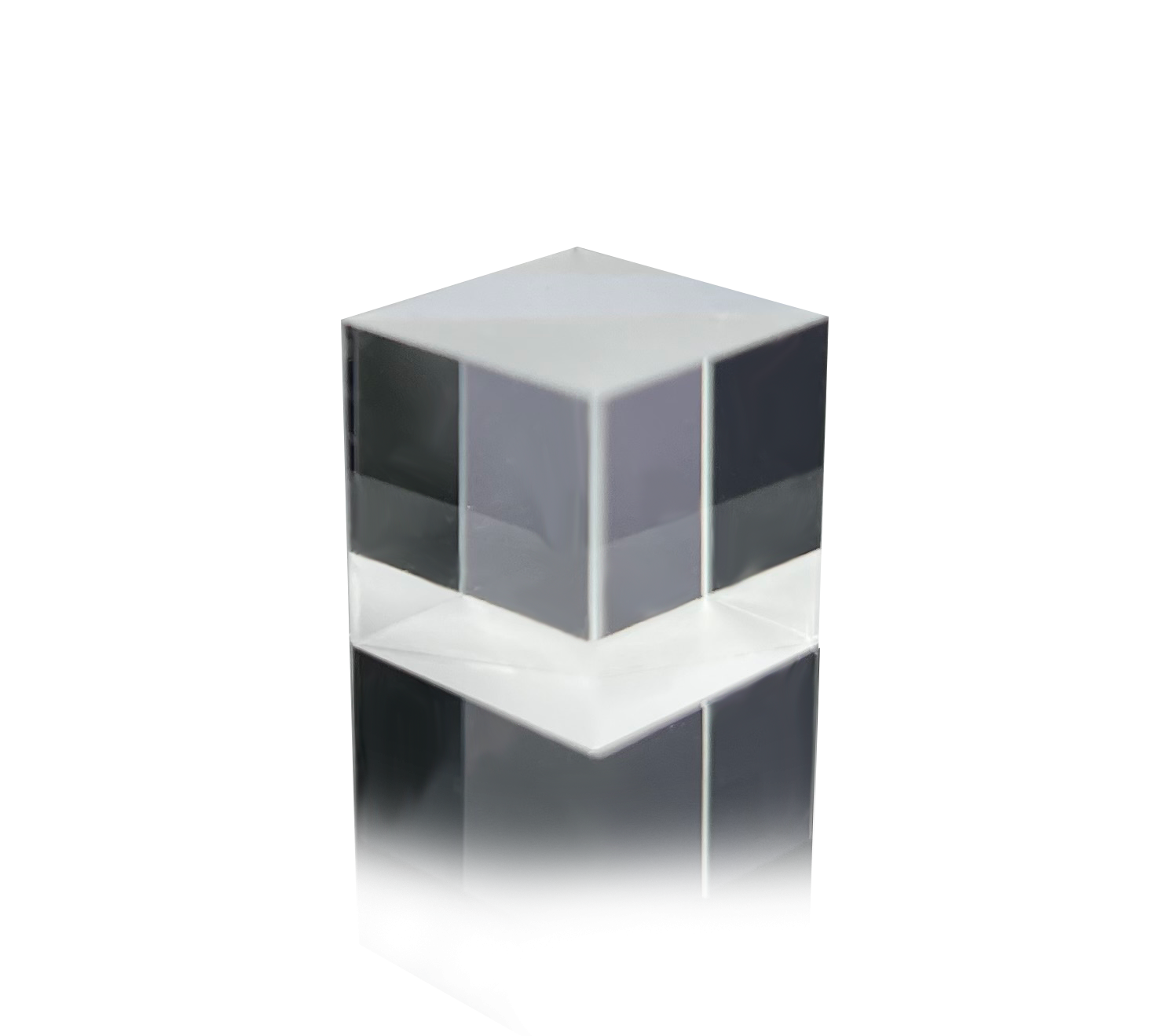

Polarization film, polarization film has plate polarization film and cubic prism polarization film two kinds. The former is based on the difference of effective refractive index of p- and S – components of oblique incident light, resulting in different bandwidths and narrow polarization bands, while the latter is based on the brewster Angle condition that all interfaces meet, resulting in larger polarization bandwidths and extinction ratio of more than 2000.

Non-Polarization film,There are metal depolarized film and all dielectric depolarized film, and depolarized film and depolarized cut-off filter. The so-called depolarization means that the transmission or reflection of p- and S – components in a certain band is required to be the same at oblique incidence.